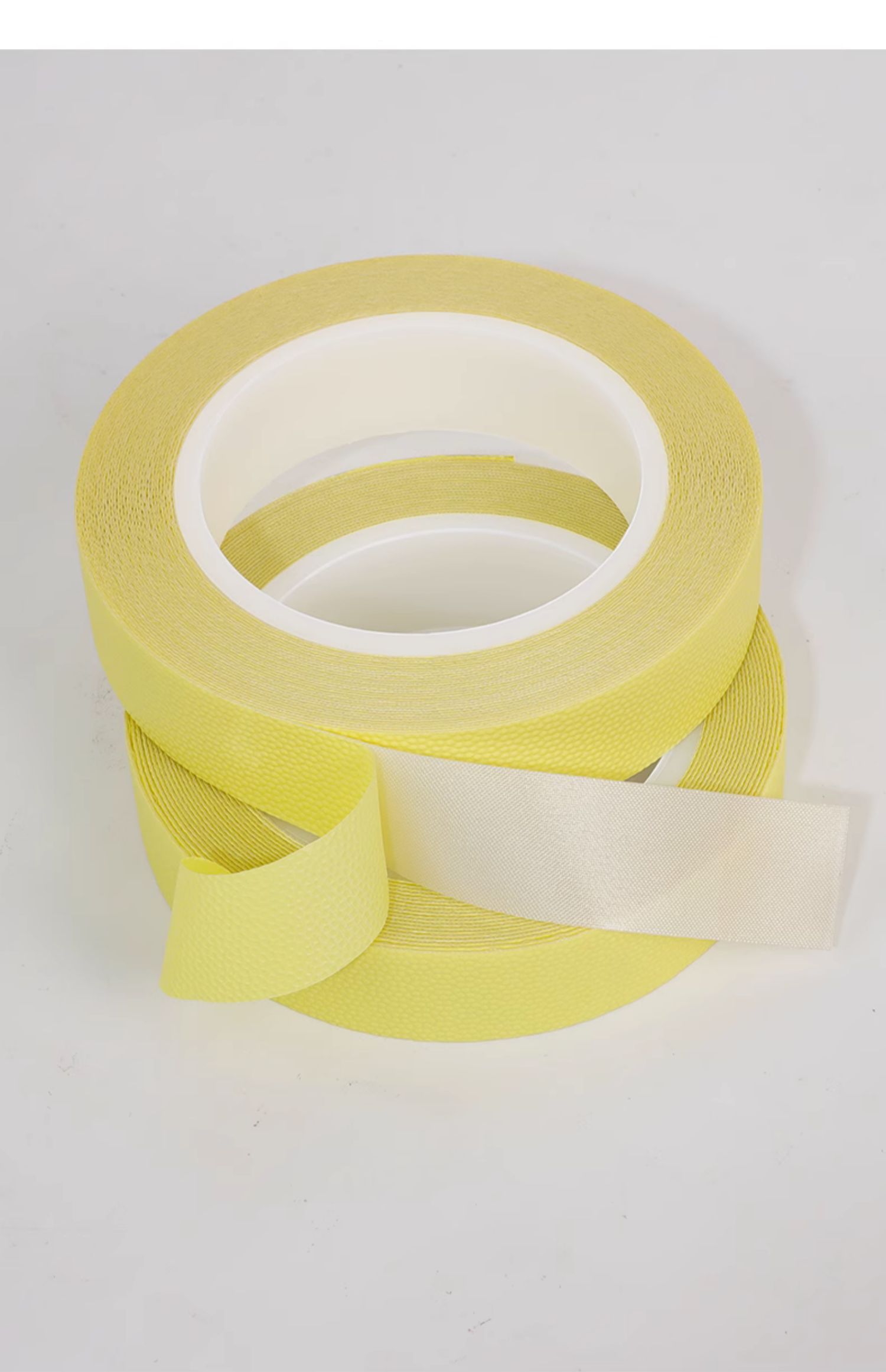

Plasma Masking Tape Description:

Plasma masking tape is an innovative material designed to facilitate precise and controlled plasma-related processes in various scientific, industrial, and research applications. This specialized tape combines unique properties that enable it to interact with plasma and assist in creating, shaping, or directing plasma discharges. We are professional industrial adhesive tape manufacturer, who can offer the OEM & ODM service to each customer.

Main Features:

Plasma Interaction: Plasma masking tape is engineered to interact with plasma discharges, allowing for controlled initiation, confinement, or manipulation of plasma in specific patterns or configurations.

Heat Resistance: The tape exhibits exceptional heat resistance to withstand the high temperatures generated during plasma processes without compromising its structural integrity.

Dielectric Properties: Plasma masking tape is typically dielectric in nature, meaning it has minimal electrical conductivity. This property prevents unwanted interference with plasma discharge and ensures a focused plasma formation.

Adhesive Compatibility: The tape’s adhesive properties are chosen carefully to withstand plasma conditions, maintaining secure attachment even in high-energy plasma environments.

Flexibility and Conformability: The tape’s flexibility and conformability enable it to be easily applied to various surfaces and shaped into desired forms to guide plasma discharges.

Plasma Masking Tape Application:

Plasma Etching and Patterning: Plasma masking tape could be used to mask specific areas of a substrate during plasma etching processes, enabling precise patterning and material removal.

Plasma Deposition and Surface Modification: The tape might assist in directing plasma-enhanced chemical vapor deposition (PECVD) or plasma coating processes, allowing for controlled deposition and surface modifications.

Plasma Cleaning and Activation: Plasma masking tape could play a role in cleaning and activating surfaces by guiding plasma discharges to specific areas, thereby enhancing adhesion and surface properties.

Plasma-Assisted Nanofabrication: In nanotechnology applications, the tape could be utilized to create nanostructures through controlled plasma-assisted fabrication techniques.

Plasma Research and Experimentation: Plasma masking tape might find use in laboratory settings for conducting experiments involving plasma, enabling researchers to explore and manipulate plasma phenomena.

Plasma Masking Tape Model List:

| Product Number: | Liner: | Total Thickness: | Adhesion to Steel: |

|---|---|---|---|

| XH-300PMT/L | Yes | 300 microns | A Side: 11 N/25mm B Side: 3 N/25mm |

Plasma Masking Tape Actual Show Video:

Why Choose Us:

– Firstly, we are a professional manufacturer, with 16 years of adhesive tape production experience, has a huge advantage in price and quality.

– Secondly, we have a large number of customers and fast transportation channels to ensure the timeliness of customers receiving goods.

– Finally, we can provide quality assurance services for each customer, if there is a quality problem, free return.

– The Most important thing is that we always focus on becoming the world’s top adhesive tape manufacturer, the quality of our products is perfectly equal to that of 3M brands.