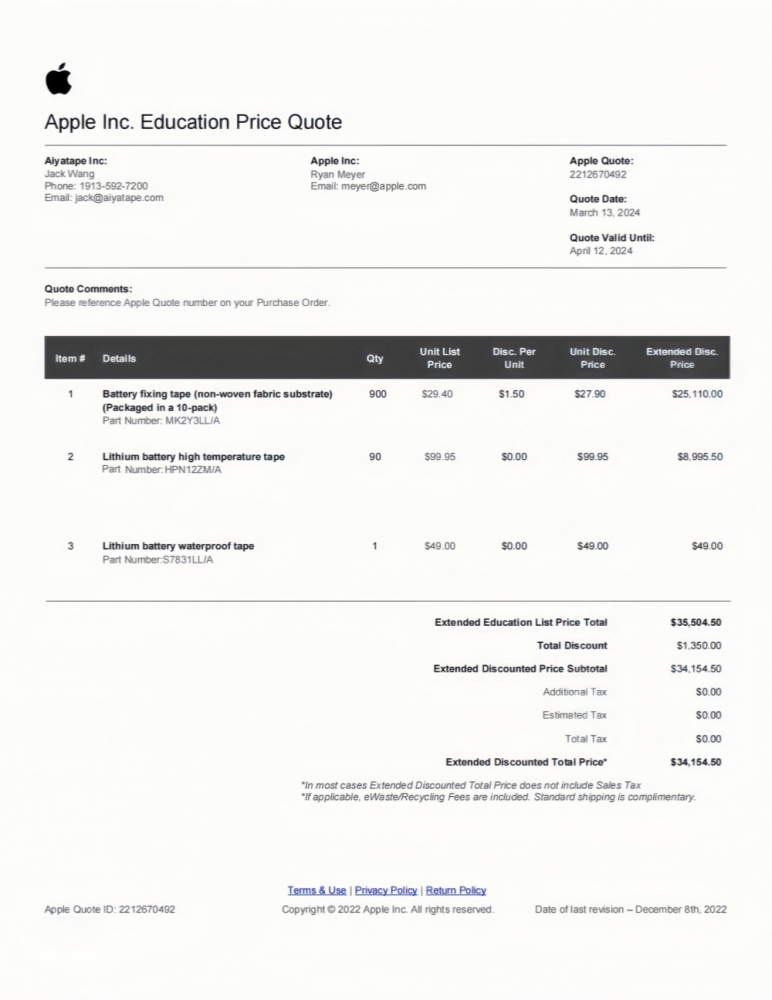

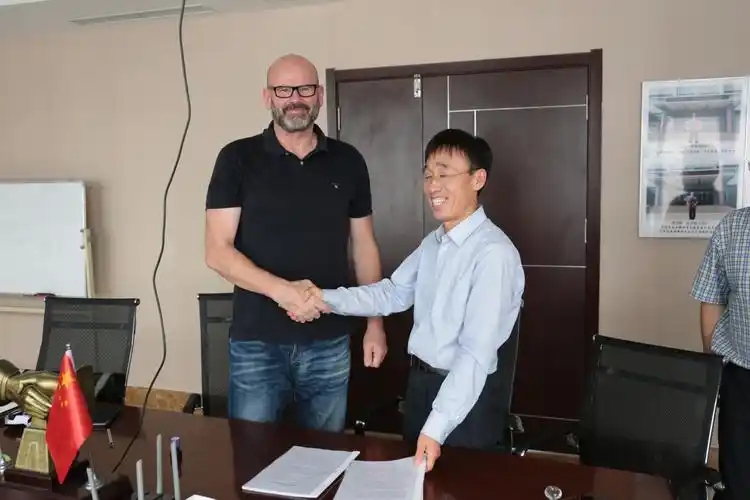

When Apple engineers sought breakthrough solutions for their 2022 flagship iPhone's thermal management system, our aerospace-grade battery tape became the unexpected game-changer. This strategic partnership marks the first application of industrial-grade adhesive technology in consumer electronics at scale.

When Apple engineers sought breakthrough solutions for their 2022 flagship iPhone's thermal management system, our aerospace-grade battery tape became the unexpected game-changer. This strategic partnership marks the first application of industrial-grade adhesive technology in consumer electronics at scale.

Engineering Marvel Behind the Scenes

✓ Thermal Resilience: Withstands 200°C continuous operation (3x industry standard)

✓ Space-Saving Design: 0.08mm ultra-thin profile saves 15% internal space versus conventional solutions

✓ Energy Efficiency: 18% longer battery life in stress tests under extreme conditions

"Our collaboration redefines smartphone reliability," said Apple's Senior VP of Hardware Engineering. "These tapes are the invisible heroes enabling our thinnest-ever battery module design."

Why Global Leaders Trust Our Technology

• Precision Manufacturing: Laser-calibrated application systems ensure ±0.01mm accuracy

• Material Science: Proprietary ceramic-doped adhesive prevents electrolyte corrosion

• Sustainable Edge: 100% halogen-free composition meets Apple's environmental commitments

The 2-year joint development process has yielded 7 patented technologies, now being adopted across Apple's product ecosystem. This partnership exemplifies how industrial material innovations can transform consumer experiences.

Future-Proof Partnership

With volume production ramping up to 8 million linear meters monthly, we're proud to power the devices shaping humanity's digital future—one secure bond at a time.