AIYA TAPE Launches Fully Automatic High-Speed Harness Tape Coating Machine

Technical Specifications

Model: XZ-TU1800 Optimized Coating Line1

Core Features:

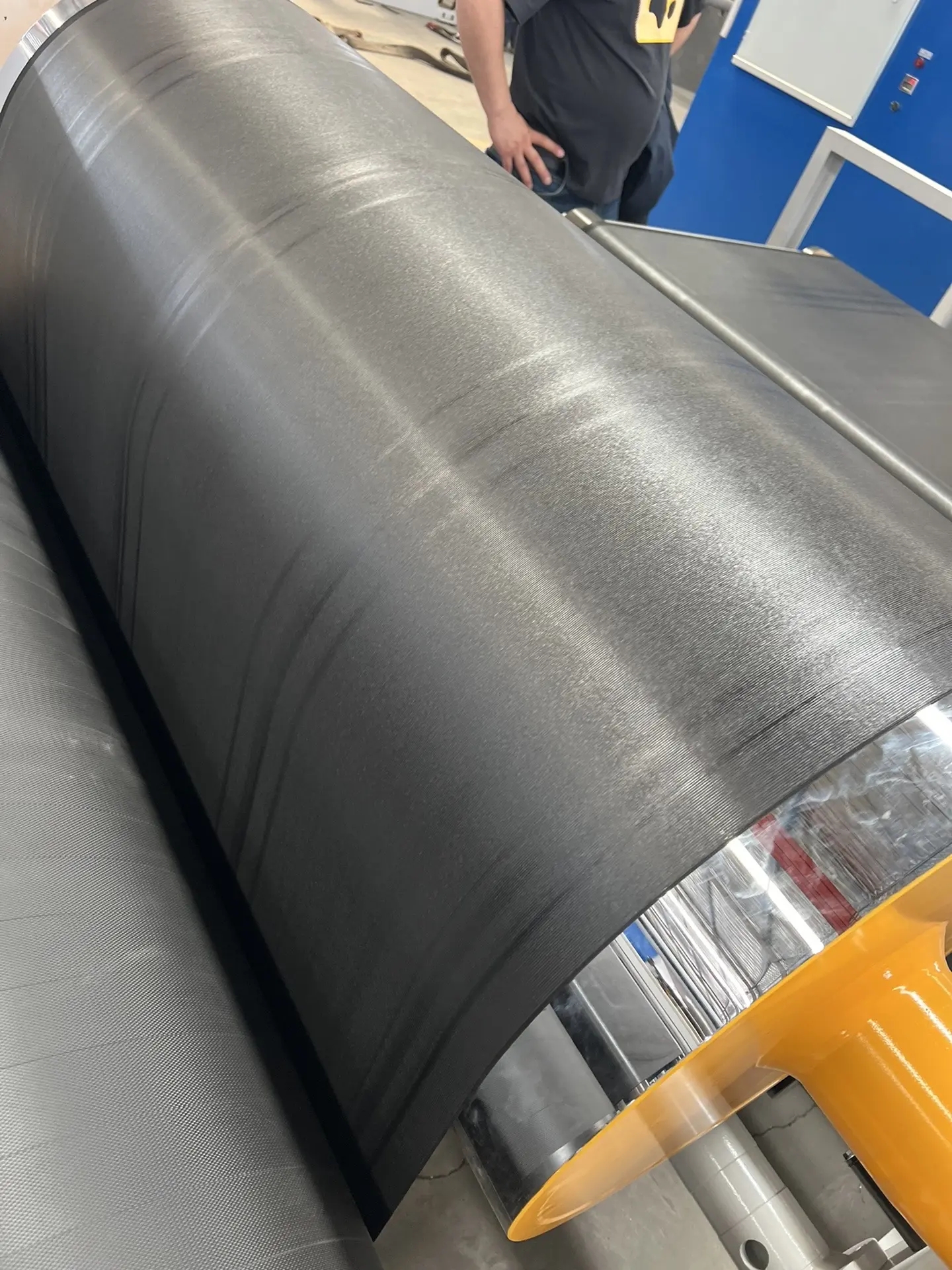

Chromium-plated Coating Roll: Supports cloth/non-woven substrates with coating uniformity of ±0.003mm

Dual-cycle Drying System: Integrated coal furnace + layered cooling chambers, improving thermal efficiency by 25%17

Hydraulic Edge Guiding: Corrects substrate deviation dynamically with ≤0.1mm precision1

Intelligent Control System:

▍ Synchronous Drive Technology

Variable frequency speed control enables 180 meters/minute line speed, accommodating 600mm-diameter rolls.

▍ PLC + HMI Integration

Touchscreen interface monitors adhesive volume (2-10g/m²) and tension fluctuation in real-time27.

Key Innovations

Process Breakthroughs

Dual Coating Roll System (2024 Patent): Enables solvent-based/water-based adhesive dual-mode operation7

Silicone Chill Roll Vortex Unit: Eliminates coating wrinkles - an industry pain point1

Smart Manufacturing

AI Vision Inspection: Detects coating defects and triggers auto-compensation7

Auger Stirring Mechanism: Prevents adhesive solidification, boosting yield to 99.5%79

Performance Metrics Matrix

Deployment reinforces AIYA TAPE’s dominance in East China’s EV supply chain, projecting ¥180M annual revenue growth8. Aligned with global lithium battery coater market (¥15.6B demand)8, Phase II smart coating center is under planning.