application

1.High -temperature insulation wrapped around the electronic industry transformers, motors, coils, capacitors, and frequency conversion power suppliers.

2.Suitable for covering and protection during printing line boards (PCB), SMT tin furnaces, and peak welding.

3.High -end electrical insulation protection and lithium battery positive&negative poles.

4.The lithium battery manufacturing is bundled.

Property

| 项 目Test items | 测试方式Test method | 单位Unit | 典型值Typical value | |

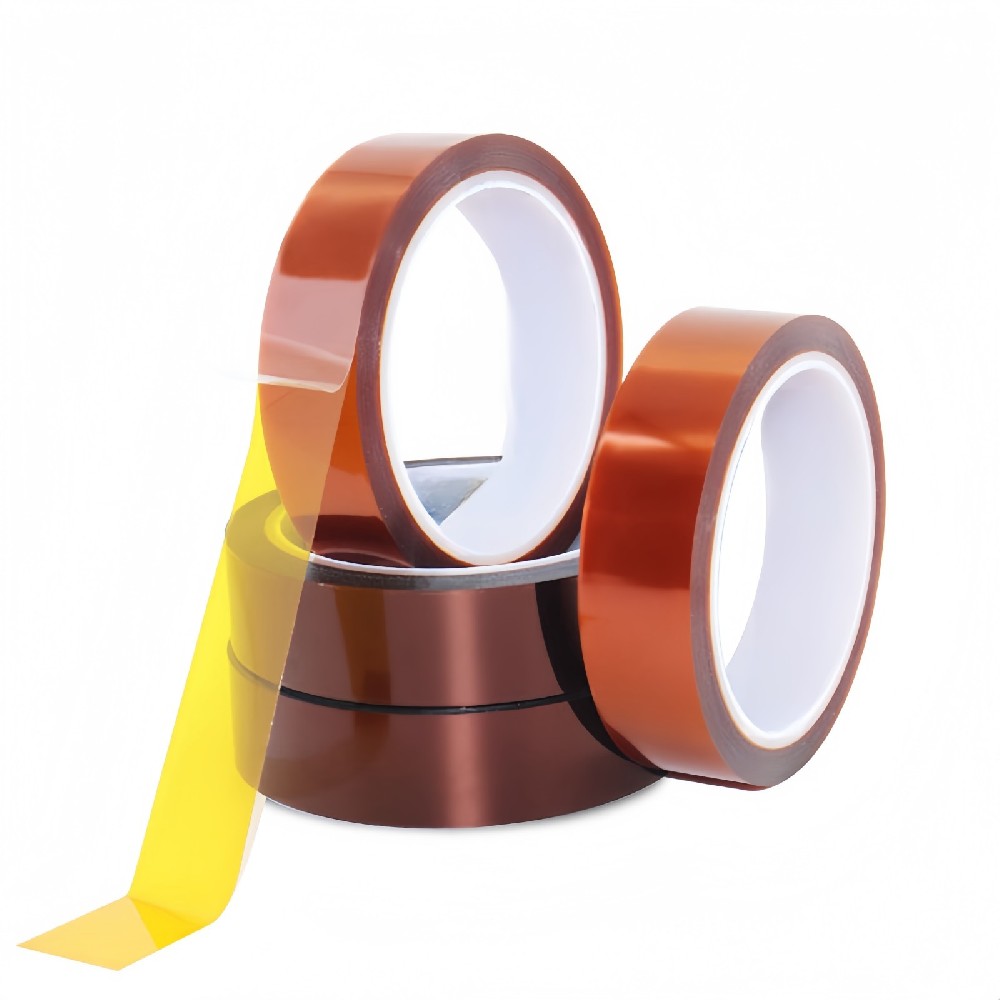

| 颜色Color | 目测Visual inspection | – | 茶色Dark Brown | 茶色Dark Brown |

| 胶系Type of glue | – | – | 硅胶 Silicone | 硅胶 Silicone |

| 基材Base material | – | – | 聚酰亚胺膜 Polyimide film | 聚酰亚胺膜 Polyimide film |

| 基材厚度 Substrate thickness | ASTM D-3652 | mm | 0.025 | 0.05 |

| 总厚度Total thickness | ASTM D-3652 | mm | 0.06 | 0.08 |

| 剥离强度Peel strength(180°) | ASTM D-1000 | N/inch | ≥5 | ≥5 |

| 拉伸强度Tensile strength | ASTM D-1000 | N/inch | ≥100 | ≥200 |

| Back anti static index | / | Ω | 106~1010 | 106~1010 |

| Elongation at break | ASTM D-1000 | % | ≥45 | ≥55 |

| Voltage resistance | GB/T72792-1998 | Kv | 5 | 7 |

| Temperature range | GB∕T 32368-2015 | ℃ | -73~260 | -73~260 |

description

Product Features

1.Excellent Insulation

2.Breakdown Voltage

3.High Temperature Resistance

Features

1. No residual adhesive: imported silicone pressure-sensitive adhesive and other high-quality adhesives are used. After the tape is torn off, there will be basically no residual adhesive on the surface of the adhered object, avoiding pollution and damage to the surface of the adhered object.

2. Good processability: the coating accuracy can reach ±2.5μm, no scratches or wire drawing, good shearing performance, easy to perform die-cutting, punching and other processing operations, and can meet the use requirements of different shapes and sizes.

Supplementary application scenarios

New energy field

1. Lithium battery production: In the production process of lithium batteries, it is used for the fixation and isolation of pole pieces and the packaging of battery packs to prevent safety problems caused by static electricity, and at the same time, it can maintain stable performance in processes such as high-temperature baking.

2. Solar photovoltaic: In the manufacture of solar panels, it can be used to fix and protect battery pieces, connecting lines, etc. Its antistatic and weather resistance can ensure long-term stable use in outdoor environments.

Automotive electronics field

1. Engine control unit: used for insulation and 2. Antistatic protection of electronic components such as engine control units (ECUs) to ensure the stable operation of electronic equipment in complex environments such as high engine temperature and vibration.

3. Car display screen: During the assembly process of the car display screen, the circuit board, backlight source and other components of the display screen are fixed and protected against static electricity to improve the reliability of the product.