application

1. Surface protection during product transportation.

2. Protection of all kinds of lenses and screen engineering.

3. Protection of plastic parts such as plastic cases and keyboards.

4. Die-cutting carrier and transfer of various films and tapes and waste discharge.

5. Different viscosity of protective film, can be used as a support carrier for different thickness of foam die-cutting.

6.Temporary transfer and fixing of electronic products.

Property

| Property | ||||||||

| Product Code Technical Parameters | P6000S1-25 | P6000S3-25 | P6000S5-25 | P6000S8-50 | P6000S12-50 | P6000S18-50 | P6000S30-75 | P6000S45-75 |

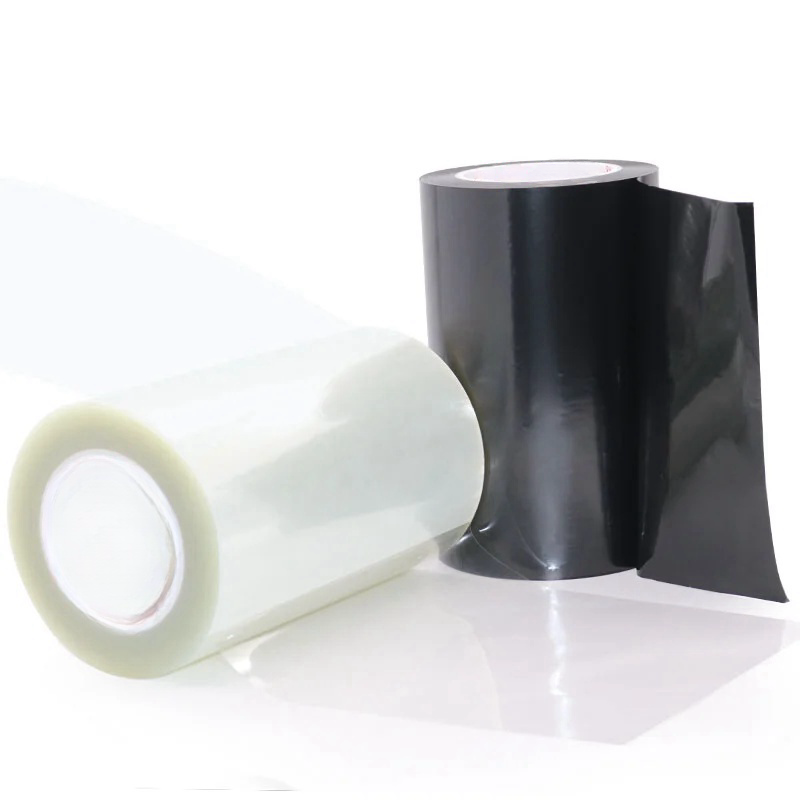

| Color | Transparent/White/Blue/Black/Red/Green/Matte(Customization) | |||||||

| Total Thickness[mm] | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 |

| Backing Thickness[mm] | 0.025/0.038/0.05/0.075 | |||||||

| Release Film Total Thickness[mm] | 0.025 | 0.025 | 0.025 | 0.05 | 0.05 | 0.05 | 0.075 | 0.075 |

| Backing | PET | |||||||

| Adhesive | Silicone | |||||||

| 180°Peel Strength[g/inch] | 1~3 | 3~5 | 5~8 | 8~12 | 12~18 | 18~30 | 30~45 | 45~65 |

| Tensile Strength[N/inch] | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 |

| Elongation At Break[%] | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 |

| Long-Term Temperature Resistance[℃] | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 |

| Short-Term Temperature Resistance[℃] | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

description

Features

Physical properties

High light transmittance: It uses a transparent PET substrate with high light transmittance, which does not affect the display effect.

Flexibility and fit: It can adapt to curved or uneven surfaces, automatically adsorb and discharge bubbles.

Optional thickness: Different thicknesses (such as 50μm, 75μm) are provided to meet the needs of buffering or lightness.

Adhesion performance

Low viscosity and high adsorption: Silicone glue has both low initial viscosity and long-lasting adsorption, easy to stick and tear without residual glue.

High temperature resistance: It can withstand high temperatures above 120℃ and is suitable for processes such as baking paint and welding.

Environmental adaptability

Chemical resistance: It is resistant to acids, alkalis and organic solvents, suitable for electronic component cleaning or industrial processing environments.

Anti-static: It reduces static adsorption of dust and protects sensitive electronic devices.

Cleanliness

Dust-free coating process: The production process is completed in a clean workshop, and there are no defects such as white spots and scratches on the surface.

Application areas

Electronics and optical industries

Surface protection of mobile phones, tablets, and computer screens.

Temporary protection in LCD and OLED panel manufacturing process.

Carrier or fixation of polarizer and touch module.

Precision manufacturing and processing

Anti-scratch protection during stamping or electroplating of hardware (such as stainless steel plate and aluminum plate).

Shielding protection during spraying or printing of plastic shell (such as ABS and acrylic).

Insulation and fixation of lithium batteries and flexible circuit boards.

Automobile and medical industry

Anti-scratch protection of automobile dashboard and central control screen.

Antibacterial and dustproof protection of medical equipment (such as monitor screen).

Transportation and packaging

Anti-scratch damage of long-distance transportation of glass and ceramic products.

Surface dust protection of finished products after electronic product assembly.

Special process assistance

As a carrier of foam and double-sided tape in die-cutting processing.

Temporary fixation in high temperature environment (such as engine component assembly).