application

1. Surface protection during product transportation.

2. Protection of all kinds of lenses and screen engineering.

3. Protection of plastic parts such as plastic cases and keyboards.

4. Die-cutting carrier and transfer of various films and tapes and waste discharge.

5. Different viscosity of protective film, can be used as a support carrier for different thickness of foam die-cutting.

6.Temporary transfer and fixing of electronic products.

Property

| Property | ||||||||

| Product Code Technical Parameters | P4000A1-25 | P4000A3-25 | P4000A5-25 | P4000A8-50 | P4000A12-50 | P4000A18-50 | P4000A30-75 | P4000A45-75 |

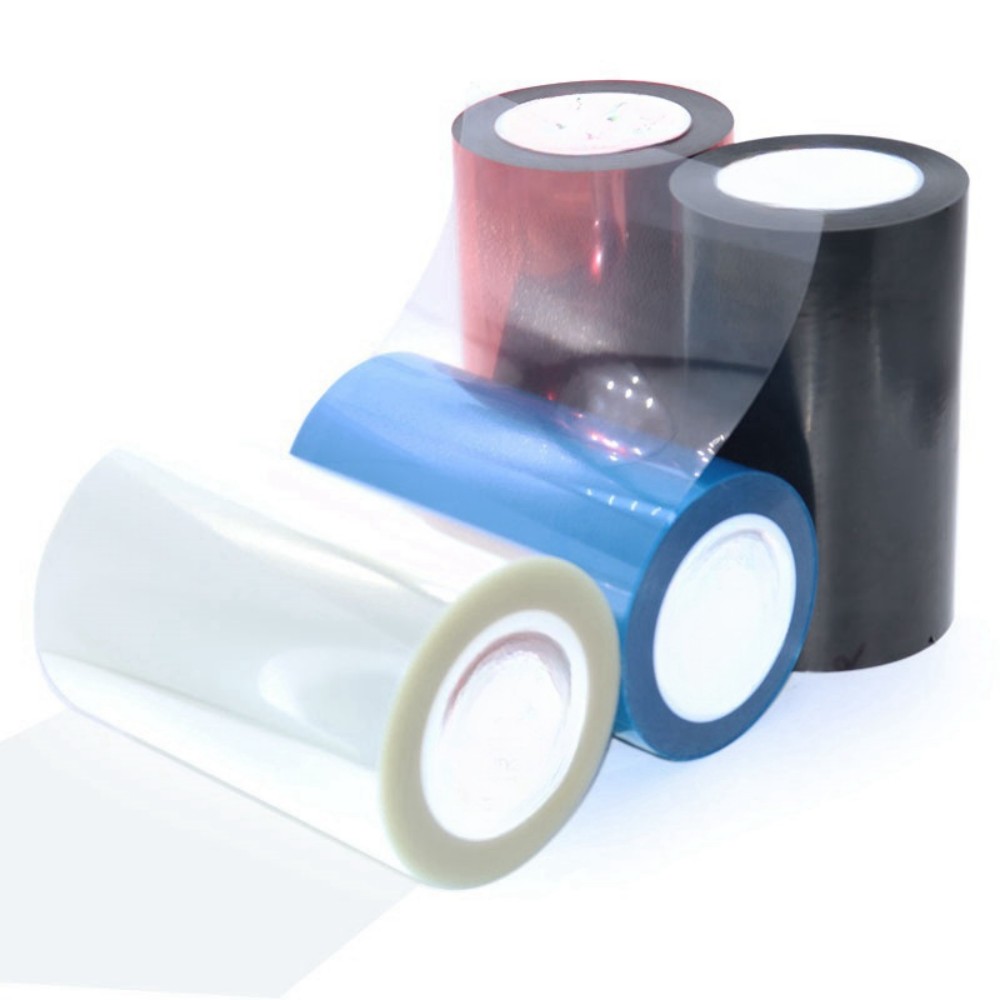

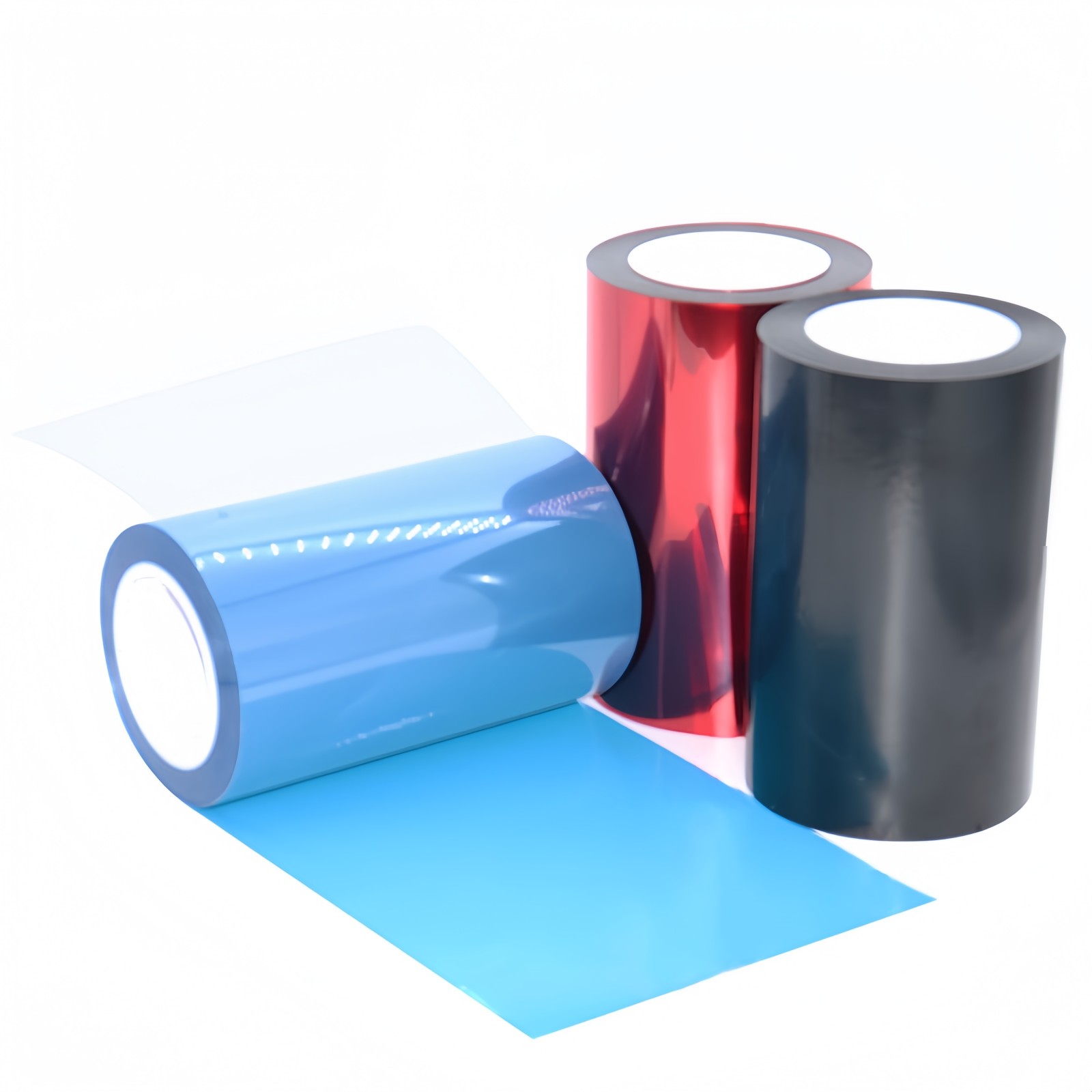

| Color | Transparent/White/Blue/Black/Red/Green/Matte(Customization) | |||||||

| Total Thickness[mm] | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 |

| Backing Thickness[mm] | 0.025/0.038/0.05/0.075 | |||||||

| Release Film Total Thickness[mm] | 0.025 | 0.025 | 0.025 | 0.05 | 0.05 | 0.05 | 0.075 | 0.075 |

| Backing | PET | PET | PET | PET | PET | PET | PET | PET |

| Adhesive | Acrylic | Acrylic | Acrylic | Acrylic | Acrylic | Acrylic | Acrylic | Acrylic |

| 180°Peel Strength[g/inch] | 1~3 | 3~5 | 5~8 | 8~12 | 12~18 | 18~30 | 30~45 | 45~65 |

| Tensile Strength[N/inch] | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 |

| Elongation At Break[%] | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 |

| Long-Term Temperature Resistance[℃] | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Short-Term Temperature Resistance[℃] | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

description

Features

High viscosity and strong adhesion: Double-sided coated acrylic adhesive has excellent viscosity and can be firmly attached to the surface of various materials. In the assembly of electronic products, it can ensure the close connection between parts; in the bonding of automotive interior parts, it can make parts of different materials stably combined and not easy to fall off.

Good weather resistance: It has excellent anti-aging, UV resistance and temperature resistance, and can maintain stable performance under different environmental conditions, such as high temperature, low temperature, humidity, etc. It can be used for surface protection of outdoor billboards. The protective film is not easy to age, turn yellow or lose viscosity after long-term exposure to sunlight and wind and rain.

Chemical stability: It has good tolerance to chemical substances such as acids, alkalis, and organic solvents. In the chemical, pharmaceutical and other industries, it can avoid chemical erosion when used to protect the surface of equipment, instruments or product packaging.

High transparency: The PET substrate itself has good optical properties, and the high light transmittance of acrylic adhesives makes the light transmittance of the protective film usually reach more than 90%. When used for the protection of optical lenses, display screens and other products, it will not have a significant impact on light transmission and visual effects.

Flexibility and stretch resistance: PET material gives the protective film high flexibility and stretch resistance, is not easy to break or tear, can adapt to objects of different shapes and surfaces, and can withstand various stretching, bending and other operations during the die-cutting process to ensure that the protective film remains intact in complex processing.

Easy to process: It can be easily processed by die-cutting, slitting, punching and other processing operations. It can be processed into various shapes and sizes according to different application requirements to meet the personalized protection needs of parts and products in the electronics, automobile, packaging and other industries.

No residual glue: When the protective film needs to be removed, it can be easily peeled off, and no glue will remain on the surface of the protected object, which will not affect the subsequent use or appearance of the protected object.

Application field

Electronic field

Screen assembly: In the production process of screens of mobile phones, tablets, laptops, etc., it is used to protect screen glass, polarizers and other components to prevent scratches, dust or fingerprints during the assembly process. At the same time, it plays a temporary fixing and protection role when fitting components such as backlight modules.

Fixing of electronic components: It can be used to fix electronic components, such as chips, capacitors, resistors, etc., to ensure that they remain in a stable position during circuit board assembly and transportation, and prevent damage or displacement due to vibration or collision.

Shell and button bonding: In the production of electronic equipment shells and buttons, it is used to stick parts of different materials together to enhance the connection strength between parts, while protecting the shell surface from scratches and wear.

Optical field

Optical lens bonding: It is used in the production and assembly of optical lenses to stick lenses to frames and lenses to ensure the position accuracy and optical performance of lenses, while protecting the lens surface from damage during processing and assembly.

Assembly of optical instrument components: In the manufacture of optical instruments such as microscopes, telescopes, and projectors, it is used to fix and protect optical components, such as reflectors, prisms, etc., to ensure the stability and accuracy of the optical system.

Automotive field

Interior parts pasting: It can be used to paste various parts of automotive interiors, such as dashboards, center consoles, door interior panels, seats, etc., making the assembly of interior parts more convenient, while protecting the interior surface from scratches and pollution.

Exterior parts installation: In the installation of automotive exterior parts, such as body trim, headlight cover, rearview mirror and other parts, provide reliable adhesion to ensure that the exterior parts will not loosen or fall off during the vehicle driving.

Other fields

Packaging industry: used for sealing packaging materials, label pasting, etc., to ensure the sealing of packaging and the firmness of labels, while protecting the printed patterns and materials on the packaging surface from damage.

Building decoration: In the field of building decoration, it can be used to paste decorative panels, glass films, wallpapers, etc., making the installation of decorative materials more convenient, while protecting the surface of decorative materials from scratches and pollution during the construction process.