application

1. LCD module and TP are fully bonded.

2.TSP bonding (G/F/F, G/F, P/F, etc.), explosion-proof film bonding, optical compensation film, polarizer bonding.

Property

| Property | |||||||||

| Product Code Technical Parameters | P-DB606 | P-DB607 | P-DB608 | P-DB610 | P-6015 | P-6025 | P-6050 | P-6125 | P-6175 |

| Application | Full Fit OCA | Full Fit OCA | Full Fit OCA | Full Fit OCA | Dedicated To TSP | Dedicated To TSP | Dedicated To TSP | Dedicated To TSP | Dedicated To TSP |

| Color | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent |

| Thickness[um] | 150 | 175 | 200 | 250 | 15 | 25 | 50 | 125 | 175 |

| Light Release Film Thickness[um] | 75 | 75 | 75 | 75 | 50 | 50 | 50 | 50/75 | 75 |

| Heavy Release Film Thickness[um] | 100 | 100 | 100 | 100 | 50 | 50/75 | 50/75 | 75 | 75/100 |

| Light Transmittance[%] | 93.2 | 93.2 | 93.2 | 93.2 | 92.3 | 92.3 | 92.3 | 92.3 | 92.3 |

| Haze[%] | 0.15 | 0.15 | 0.15 | 0.15 | 0.13 | 0.13 | 0.13 | 0.15 | 0.15 |

| Chromatic Aberration[L*a*b*] | 96.86 / -0.06/0.14 | 95.6 / -0.06 /0.14 | 95.6 / -0.06 /0.14 | 95.6 / -0.06 /0.14 | 96.8 / -0.06/ 0.15 | 96.8 / -0.06/ 0.15 | 96.8 / -0.06/ 0.15 | 96.8 / -0.06/ 0.15 | 96.8 / -0.06/ 0.15 |

| Refractive Index[n/25℃] | 1.478 | 1.478 | 1.478 | 1.478 | 1.478 | 1.478 | 1.478 | 1.478 | 1.478 |

| 180°Peel Strength [gf/25㎜,SUS] | > 1,300 | > 1,500 | > 1,800 | > 2,000 | > 800 | > 1,000 | > 1,200 | > 1,600 | > 1,800 |

| Retention[Min(1,000g,SUS)] | >1,000 | >1,000 | >1,000 | >1,000 | >1,000 | >1,000 | >1,000 | >1,000 | >1,000 |

| Dielectric Constant | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 |

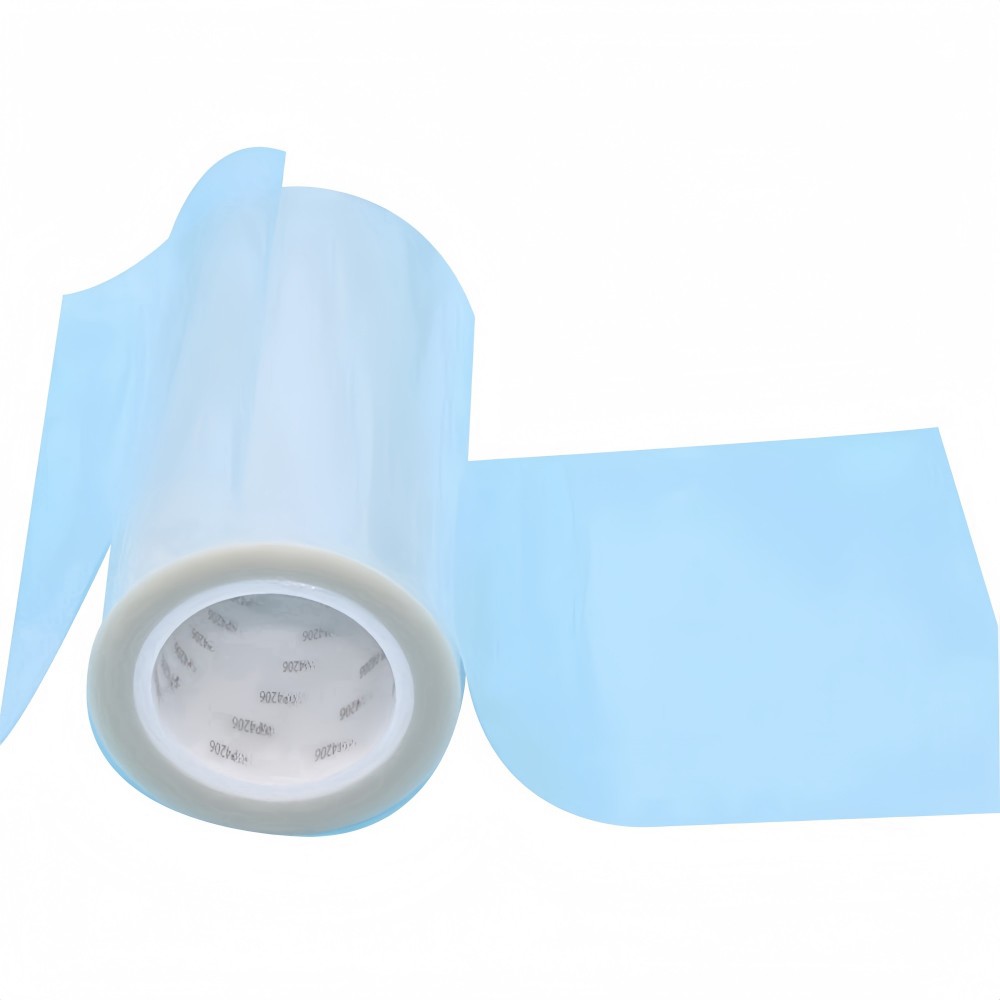

description

Structural features

Generally, the optical acrylic adhesive is made without a substrate, and a layer of release film is attached to the upper and lower bottom layers to form a double-sided adhesive tape without a substrate material.

Features

High transparency: The light transmittance is usually above 90%, and even the total light transmittance can be > 99%, which can make the light penetrate almost without loss, ensuring that the display screen is clear and sharp.

High adhesion: Different optical components can be firmly bonded together, maintaining good bonding effects under different environments, and ensuring that the layers will not easily separate.

Good flexibility: Especially in applications such as flexible displays, it can perfectly adapt to the bending and curling requirements of flexible display screens, and can still maintain its optical and mechanical properties after multiple bending.

Strong weather resistance: It has the characteristics of water resistance, high temperature resistance, and UV resistance. Under different environmental conditions, such as high temperature, high humidity, and ultraviolet radiation, it can maintain stable performance and is not prone to yellowing, peeling, and deterioration.

Small curing shrinkage: During the curing process, the volume shrinkage is very small, which can ensure that the spacing between the bonded optical components is uniform, and no deformation or stress will occur due to shrinkage, thereby affecting the optical performance.

Low haze: It can keep the surface of the bonded optical components smooth and flat, reduce light scattering, and improve the clarity and contrast of the display effect.

Excellent processability: It can be made into various shapes and specifications through various processing methods such as coating and die cutting to meet the needs of different products.

Application market

Consumer electronics field

Mobile phones: Widely used in the screen assembly of smart phones, such as bonding touch panels to cover glass, display screens to cover glass or touch panels, etc., and also used for bonding between flexible l films, amoled modules, etc. in flexible and folding screen mobile phones.

Tablets and laptops: Used in their display touch modules to achieve the bonding of panels, polarizers, touch screens and other components.

Wearable devices: Such as smart watches, etc., used to connect display screens with shells, touch screens and other components.

In-vehicle display field: used for the assembly of in-vehicle display screens, bonding the display screens with cover glass, touch screens and other components together to ensure that the display system can work stably under complex automotive use environments, such as large temperature changes, unstable humidity, vibration and other conditions.

Industrial control field: in the assembly of display screens, touch screens and other components of industrial control equipment, it can ensure stability and reliability in industrial environments and ensure long-term stable operation of the equipment.

Medical equipment field: used for bonding of display screens, optical lenses and other components of medical equipment, requiring high cleanliness, stability and biocompatibility to meet the high precision and safety requirements of medical equipment.

Optical instrument field: used for the assembly of lenses in optical lenses and the bonding and assembly of other optical devices, such as camera lenses, telescopes, etc., to ensure the relative position accuracy and optical performance of optical components.

Aerospace and military field: used for the assembly of aerospace or military optical devices, such as the bonding of display screens, military telescopes, sights and other optical components in aircraft cockpits, with extremely high requirements for reliability and stability.