application

PET Protection Film is available for Laptop, mobile phone, MNT display privacy protection; ATM, airline display, car display

Property

| Property | |||||

| Product Code Technical Parameters | P94295AH | P94450AH | P94450AS | P94360AB | P9420 |

| Product name | Privacy Film | Privacy Film | Privacy Film | Privacy Film AB Glue | Privacy film Substrate |

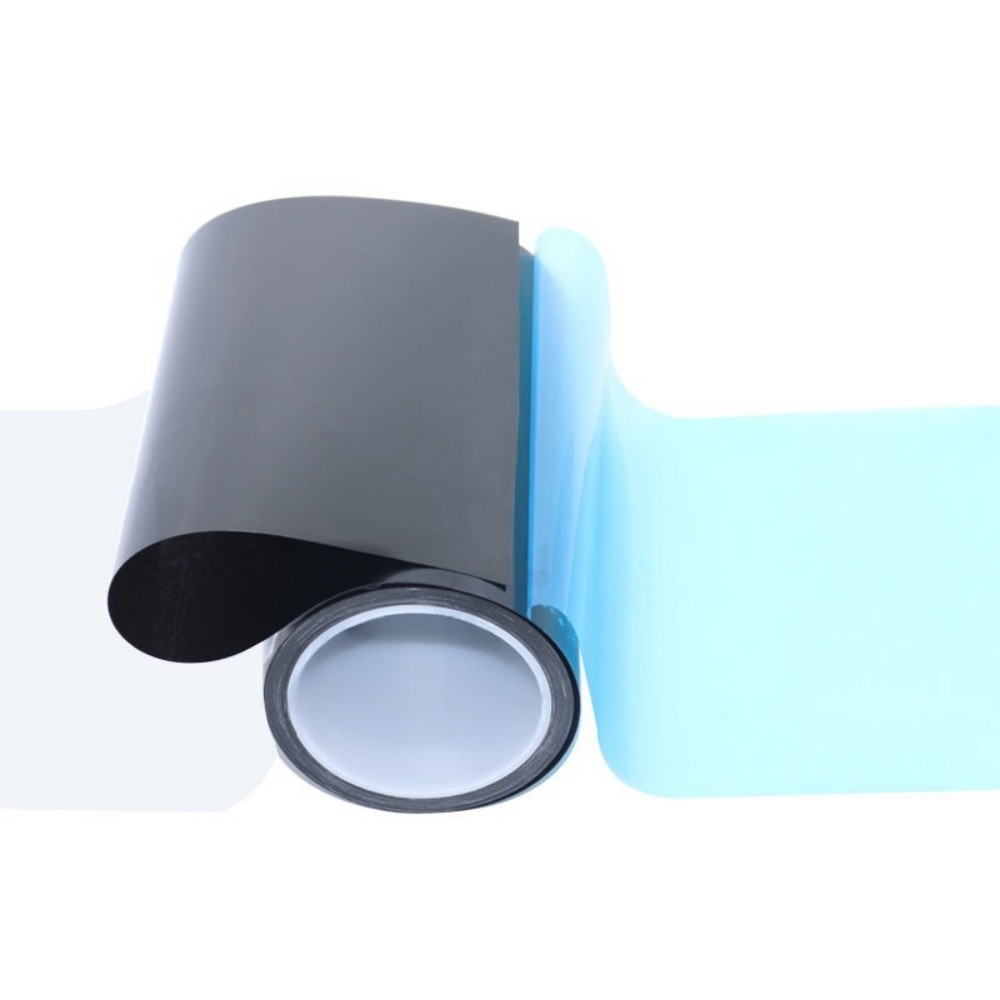

| Color | Dark Transparent | Dark Transparent | Dark Transparent | Dark Transparent | Dark Transparent |

| Total Thickness [um] | 295 | 450 | 450 | 360 | 200 |

| Direction Of Anti-peep | 2WAY | 4WAY | 4WAY | 2WAY | 2WAY |

| Surface Treatment | AG/HC | AG/HC | AG/Si | AG/HC | – |

| Angle Of Anti-peep | 30D | 30D | 30D | 30D | 30D |

| Transparency[%] | 65 | 50 | 50 | 65 | 65 |

| Surface Hardness | >H | >H | >H | >H | >H |

| Haze[%] | <40 | <40 | <40 | <40 | <40 |

description

Features

High transparency: PET protective film has excellent optical properties, high transparency, and usually a light transmittance of more than 90%. It can keep the original appearance and display effect of the protected object intact, and maintain a clear visual effect while protecting it. It is suitable for products with high display clarity requirements, such as electronic screens.

Good mechanical properties: It has high tensile strength and tear resistance, is tough and durable, not easy to break, can effectively resist external friction, scratches and collisions, and provide reliable physical protection for the protected objects. It can be used to protect the surface of products that are susceptible to friction and collision, such as mobile phones and tablet screens.

Chemical stability: It has good tolerance to many chemicals, is not easily corroded by acids, alkalis, organic solvents, etc., can maintain stable performance in different chemical environments, and is suitable for the protection of products that may be exposed to chemicals, such as industrial equipment, automotive parts, etc.

Dimensional stability: Under different temperature and humidity conditions, the size of the PET protective film changes little, and it can maintain good shape and dimensional accuracy, ensuring close fit with the protected object, and will not wrinkle or warp due to environmental changes. It is suitable for the protection of precision electronic components with high dimensional accuracy requirements.

Easy processing: It can be made into protective films of various shapes and specifications through various processing methods such as coating, printing, and die-cutting to meet the protection needs of different products. It has strong flexibility and adaptability and can be customized according to the shape and size of different products.

Good fit: PET protective film has good fit with the surface of the protected object, can adhere tightly, is not easy to produce bubbles and fall off, and can be easily removed when needed, without leaving residual glue, and has no damage to the surface of the protected object. It is suitable for various product surfaces that require temporary or long-term protection.

Anti-static performance: Some PET protective films have anti-static function, which can effectively prevent the generation and accumulation of static electricity, avoid static electricity from damaging electronic products, etc., and protect the performance and stability of electronic components. It is often used for the protection of electronic components, circuit boards, etc. during packaging and transportation.

Application market

Electronic industry

Mobile devices such as mobile phones and tablets: used to protect screens and shells to prevent scratches, wear and dirt during production, transportation and use, and can also play a certain anti-glare and anti-fingerprint role.

LCD monitors and TVs: protect the screen from damage during transportation and installation. Some high-end products also use PET protective films with special optical properties to improve the display effect.

Electronic components: protect electronic components such as chips and circuit boards during production, storage and transportation to prevent damage from static electricity, dust and moisture.

Automotive industry

Automotive interior: used to protect interior parts such as car dashboards, center consoles, seats, etc., to prevent scratches, stains and ultraviolet aging, extend the service life of the interior, and maintain the beauty of the car.

Automotive exterior: can be used to protect the surface of the car body, window glass and other parts to prevent damage from stone impact, tree branch scratches and other damage during transportation and use, and can also play a certain anti-corrosion role.

Construction industry

Glass curtain wall: during the installation and use of the glass curtain wall, it plays a role in protecting the glass surface, preventing scratches, pollution and acid rain erosion, and improving the service life and beauty of the glass.

Decorative panels: used for surface protection of various decorative panels, such as aluminum-plastic panels, fireproof panels, etc., to prevent damage during processing, transportation and installation, and ensure the surface quality of the panels.

Plastic industry

Plastic film and sheet: In the production process of plastic film and sheet, it is used as a protective film to prevent the surface from being scratched and contaminated, and improve the quality and appearance of the product.

Plastic products: Such as plastic furniture, plastic pipes, etc., use PET protective film to prevent surface damage during production, transportation and storage, and maintain the integrity and beauty of the product.

Other industries

Optical lenses: Used to protect optical lenses from scratches and contamination during processing, assembly and storage, ensuring the optical performance and surface quality of the lenses.

Solar panels: Protect the glass or film on the surface of solar panels to prevent erosion by wind, sand, rain, etc. in outdoor environments, and improve the service life and power generation efficiency of the panels.

Medical devices: In the production and packaging process of medical devices, it is used to protect the surface of the device, prevent contamination and scratches, and ensure the quality and safety of medical devices.