application

1. Surface protection during product transportation.

2. Protection of all kinds of lenses and screen engineering.

3. Protection of plastic parts such as plastic cases and keyboards.

4. Die-cutting carrier and transfer of various films and tapes and waste discharge.

5. Different viscosity of protective film, can be used as a support carrier for different thickness of foam die-cutting.

6.Temporary transfer and fixing of electronic products.

Property

| Property | ||||||||

| Product Code Technical Parameters | P4000A1 | P4000A3 | P4000A5 | P4000A8 | P4000A12 | P4000A18 | P4000A30 | P4000A45 |

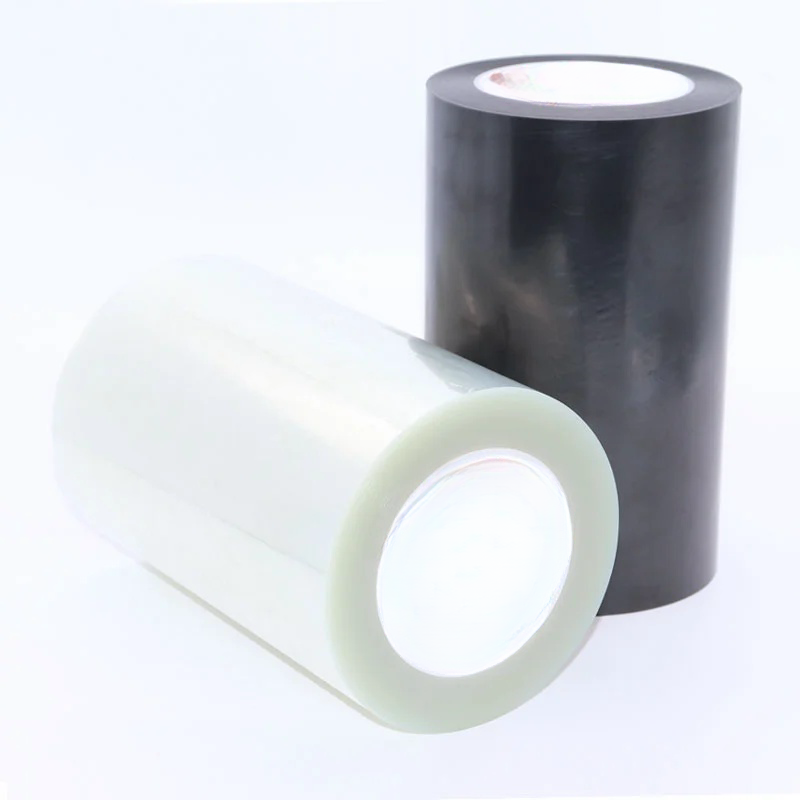

| Color | Transparent/White/Blue/Black/Red/Green/Matte(Customization) | |||||||

| Total Thickness[mm] | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 | 0.028~0.110 |

| Backing Thickness[mm] | 0.025/0.038/0.05/0.075 | |||||||

| Backing[mm] | PET | PET | PET | PET | PET | PET | PET | PET |

| Adhesive | Acrylic | Acrylic | Acrylic | Acrylic | Acrylic | Acrylic | Acrylic | Acrylic |

| 180°Peel Strength[g/inch] | 1~3 | 3~5 | 5~8 | 8~12 | 12~18 | 18~30 | 30~45 | 45~65 |

| Tensile Strength[N/inch] | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 |

| Elongation At Break[%] | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 | ≥70 |

| Long-Term Temperature Resistance[℃] | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Short-Term Temperature Resistance[℃] | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

description

Features

High transparency: The PET substrate itself has good transparency, and the high light transmittance of acrylic glue makes the light transmittance of single-sided acrylic PET protective film usually reach more than 90%, which can clearly show the original appearance of the protected object without affecting the visual effect.

Good viscosity: Acrylic glue has moderate viscosity and has suitable bonding strength for various materials such as metal, plastic, glass, etc. It can be firmly attached to the surface of the protected object during use, and can be easily peeled off when needed without leaving residual glue.

Good weather resistance: It has good weather resistance and can maintain stable performance under different temperature and climatic conditions. Whether it is high temperature, low temperature, humid or dry environment, it is not easy to have problems such as aging, embrittlement, and reduced viscosity.

Smooth surface: The product surface is smooth and flat, with high cleanliness. It is not easy to produce impurities such as paper scraps during die-cutting and other processing processes, which can effectively protect the surface of the protected object from dust, oil and other pollution.

Excellent mechanical properties: PET substrate gives the protective film high tensile strength, tear strength and wear resistance, which can effectively prevent the surface of the protected object from being scratched and scratched, and resist a certain degree of external force impact.

Application field

Electronic products: Widely used in the protection of screens, shells, keyboards and other components of electronic products such as mobile phones, tablets, laptops, LCD monitors, etc., to prevent the surface from being scratched, worn and contaminated during production, transportation and storage.

Automobile industry: Used for surface protection of automotive interior parts such as instrument panels, central control panels, door interior panels, etc. to prevent scratches or dirt during assembly; can also be used for temporary protection of automotive glass, body paint, etc.

Hardware products: Protect metal plates such as stainless steel plates, aluminum plates, copper plates and hardware parts during processing, transportation and storage to prevent scratches, oxidation, corrosion and other problems on the surface.

Plastic industry: Can be used for surface protection of various plastic plates, plastic shells, plastic films, etc. to avoid scratches, wear, dust pollution, etc. during production, processing and use.

Architectural decoration: In construction, it can be used to protect the surfaces of doors and windows, glass, marble countertops, tiles, floors, etc., to prevent them from being scratched or contaminated by cement, sand, etc. during the construction process.