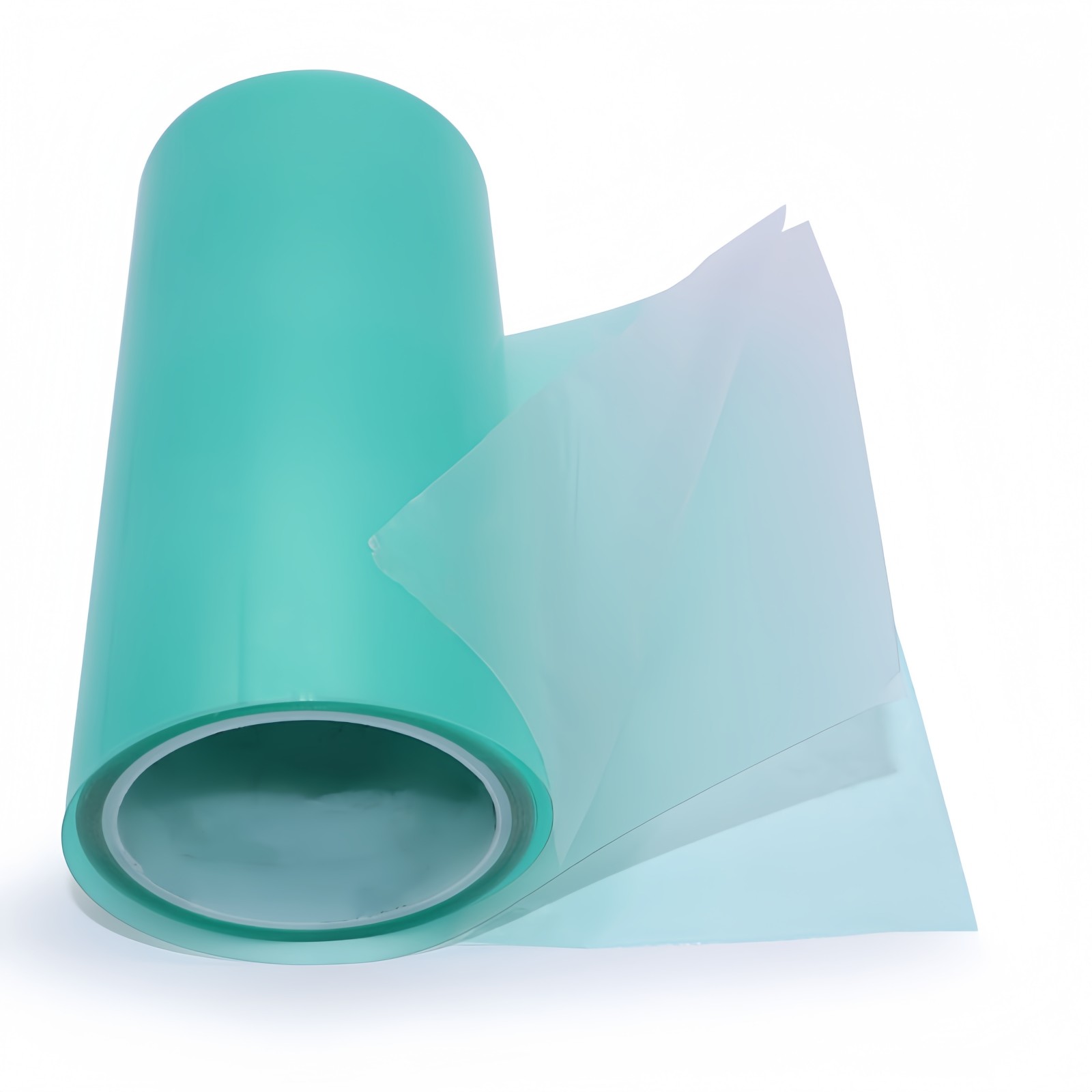

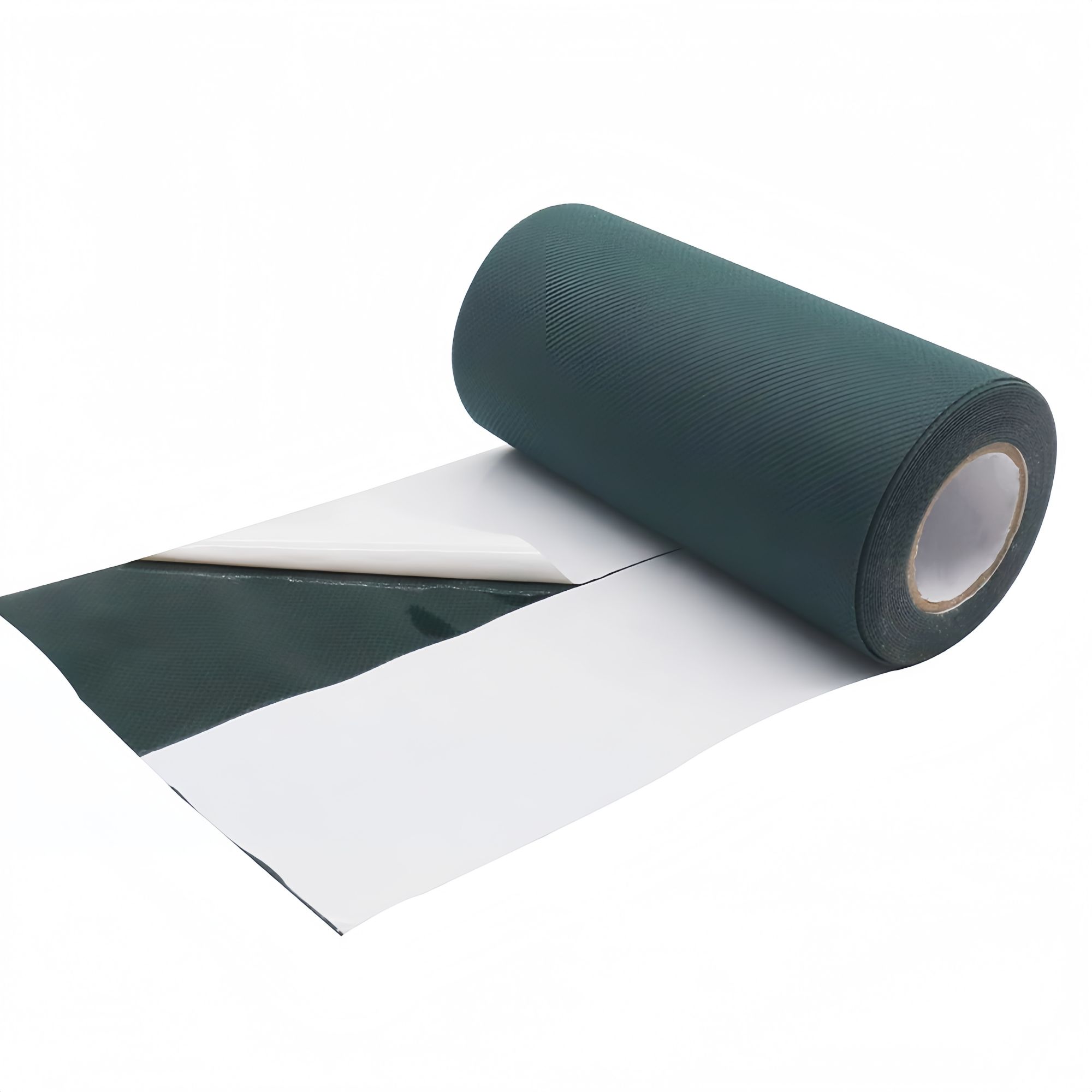

application

Automotive interior, laptop, mobile phone, tablet, home appliances, decoration, smart furniture, electric vehicle, robot vacuum cleaner and other appearance parts

Property

| Property | |||||||||

| Product Code Technical Parameters | P9790G | P9730G | P9732AG | P9745AG | P9760AG | P9777AG | P9780AG | P9708FG | P9710FG |

| Color | Transparent | ||||||||

| Total Thickness[mm] | 0.1~0.8 | 0.1~0.8 | 0.1~0.8 | 0.1~0.8 | 0.1~0.8 | 0.1~0.8 | 0.1~0.8 | 0.1~0.8 | 0.1~0.8 |

| Substrate | PC | PC | PC | PC | PC | PC | PC | PC | PC |

| UV Roughness(Ra/um) | 0.55 | 0.36 | 0.52 | 0.73 | 1.63 | 0.79 | 0.89 | 0.72 | 1.21 |

| UV Roughness(Rz/um) | 5.5 | 4.3 | 4 | 4.4 | 13.32 | 5.9 | 6.3 | 4.8 | 9.1 |

| Glossiness[%] | 18.1 | 23.6 | 36.2 | 26.2 | 18.4 | 16 | 15.7 | 15.5 | 17.3 |

| Transparency[%] | 56.5 | 64.8 | 73.2 | 67.5 | 60.3 | 44.4 | 37.8 | 36.8 | 55.3 |

| Haze[%] | 48.8 | 35.1 | 22.4 | 31.3 | 40.3 | 62.7 | 69.1 | 68.2 | 44.5 |

| Rate Of Penetration[%] | 86.1 | 85.5 | 85.2 | 84.3 | 84.7 | 87.5 | 88.2 | 87.3 | 85.5 |

description

Features

Excellent optical performance: Nano texture can scatter and refract light, reduce reflected glare, and enhance visual effects. It can achieve high light transmittance, making the display clear and colorful.

Good mechanical properties: PC material itself has high strength and strong impact resistance. Nano texture PC film can withstand certain external force extrusion and friction without being easily damaged. The surface hardness is high, with good wear resistance, and can resist scratches in daily use.

Unique surface texture: Nano-level texture gives the film a delicate and unique touch, improving product quality and grade. Different textures can bring different touch experiences such as frosted and silk.

Good chemical stability: PC material has good chemical stability. Nano texture PC film is not easy to react chemically with other substances under different environments. It is resistant to acid, alkali, and organic solvents.

Excellent processing performance: It is easy to form and process. It can be processed into products of different shapes and sizes through hot pressing, die cutting, coating and other processes to meet different application needs.

Preparation process

Nanoimprint technology: Using a template with a nano-scale pattern, the texture on the template is copied to the surface of the PC film through hot pressing or UV curing.

Photolithography technology: Using photolithography equipment, through exposure, development and other processes, a nano-scale texture structure is produced on the PC film, which has high precision but high cost.

Laser processing technology: such as femtosecond laser processing, using high-energy-density laser pulses to accurately induce nano-textures on the surface of the PC film, which can achieve complex texture designs.

Application fields

Consumer electronics field: used for display screens and shells of mobile phones, tablets, laptops, etc., to reduce screen reflections, enhance visual experience, and make the product appearance more textured.

Automotive interior field: It can be used for the decoration of automotive dashboards, center consoles, door interiors and other parts, providing unique textures and touch, and improving the quality and grade of interior decoration.

Optical display field: As a substrate for optical lenses, polarizers, diffusers, etc., its nano-texture is used to adjust light propagation and improve optical performance.

Packaging field: used as packaging materials for high-end products, such as packaging boxes for cosmetics, jewelry, etc., to enhance the aesthetics and texture of the packaging through nano-texturing.