Nano Carbon Copper Foil Tape Description:

Nano carbon copper foil tape is a specialized adhesive tape that combines the conductivity of copper foil with the enhanced properties of nano carbon materials. Here’s a description of nano carbon copper foil tape:

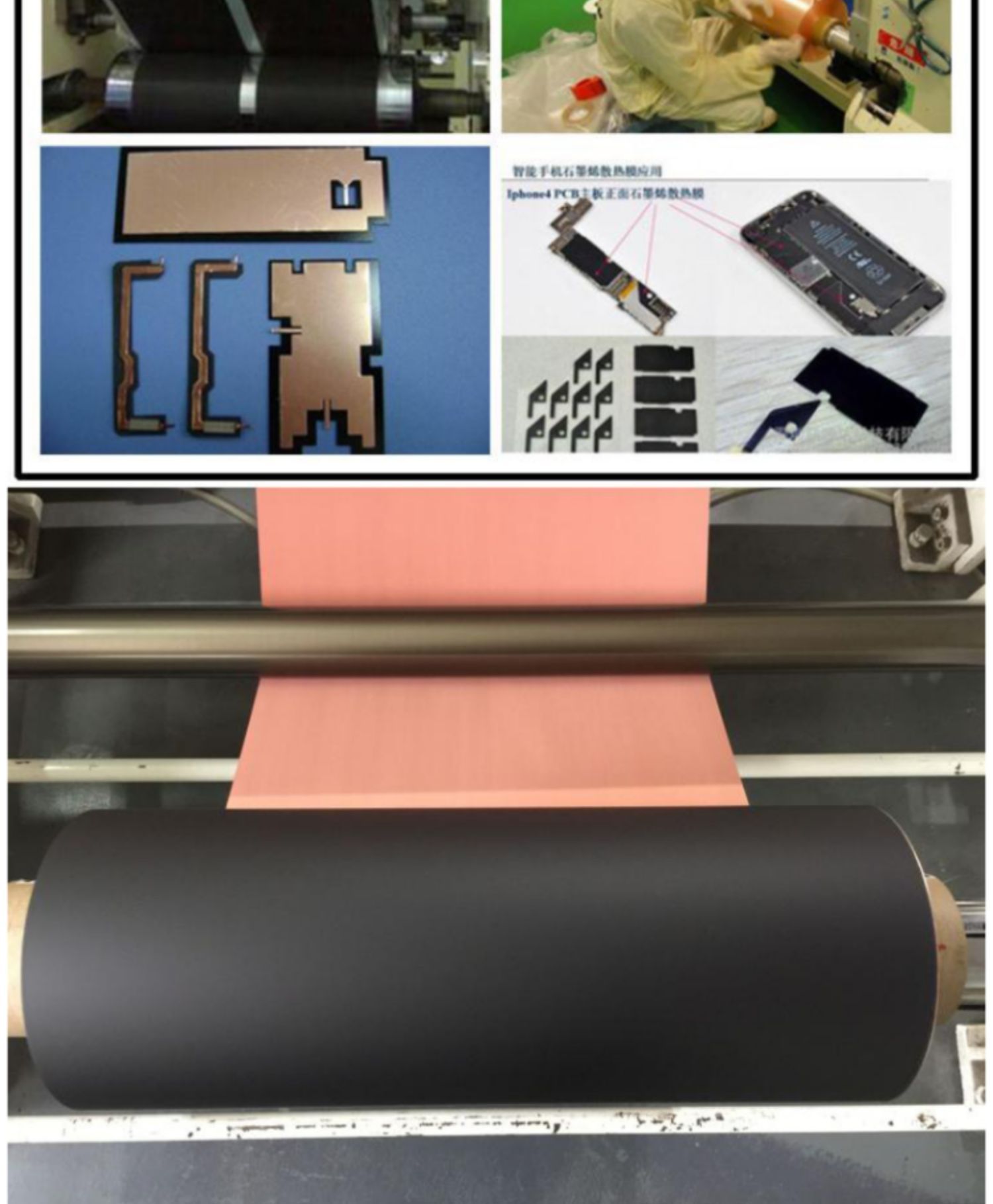

Material Composition: Nano carbon copper foil tape is composed of a thin layer of copper foil as the substrate, onto which nano carbon particles are integrated or coated. The copper foil provides excellent electrical conductivity, while the nano carbon materials enhance the tape’s mechanical strength, thermal conductivity, and other performance characteristics.

Conductivity: The copper foil component of the tape ensures high electrical conductivity, making it suitable for applications where electrical grounding, shielding, or conduction is required. The conductivity of copper allows the tape to effectively carry electrical currents and provide a reliable electrical connection.

Nano Carbon Enhancement: Nano carbon materials, such as carbon nanotubes or graphene, are incorporated into the tape to enhance its properties. These nano carbon particles contribute to improved mechanical strength, flexibility, and thermal conductivity of the tape, making it more durable and versatile compared to traditional copper foil tapes.

Adhesive Backing: Nano carbon copper foil tape features a strong adhesive backing that allows it to bond securely to various surfaces, including metals, plastics, ceramics, and composites. The adhesive is typically pressure-sensitive, ensuring easy application and reliable adhesion without the need for additional adhesives or soldering.

Thermal Conductivity: The presence of nano carbon materials in the tape enhances its thermal conductivity, allowing it to dissipate heat more efficiently. This property is beneficial for applications where heat management is crucial, such as in electronic devices, heat sinks, or thermal interface materials.

Versatility: Nano carbon copper foil tape is versatile and finds applications in various industries, including electronics, telecommunications, aerospace, automotive, and renewable energy. It is used for applications such as electromagnetic interference (EMI) shielding, grounding, circuit board repair, electrical connections, and thermal management.

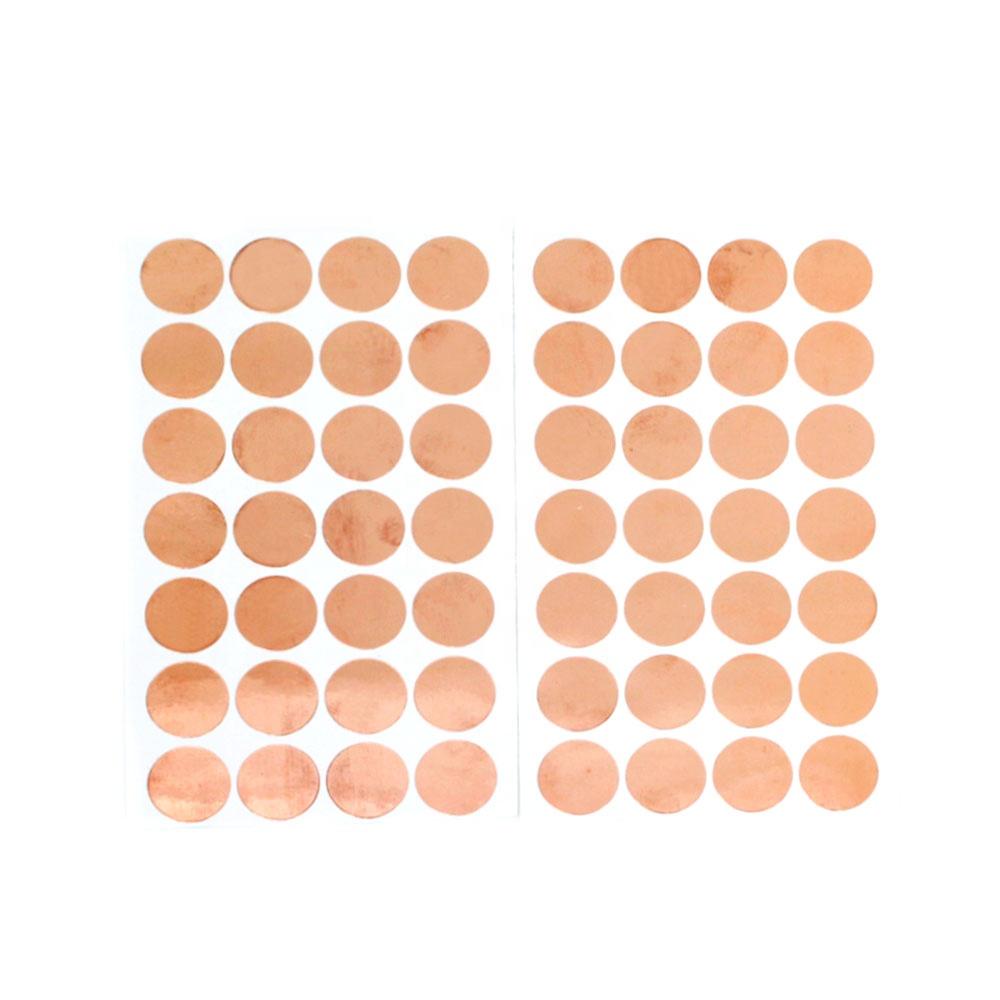

Customization: Nano carbon copper foil tape is available in different widths, thicknesses, and adhesive formulations to suit specific application requirements. Customization options allow users to tailor the tape to fit their needs accurately, ensuring optimal performance and compatibility with different materials and environments.

Overall, nano carbon copper foil tape offers a unique combination of electrical conductivity, mechanical strength, thermal conductivity, and versatility, making it a valuable material for a wide range of industrial and electronic applications where performance and reliability are critical.

Nano Carbon Copper Foil Tape Application:

Nano carbon copper foil tape has numerous applications across various industries where electrical conductivity, thermal management, and reliability are essential. Here are some common applications:

Overall, nano carbon copper foil tape offers a reliable and versatile solution for various critical applications across industries where electrical conductivity, EMI shielding, thermal management, and reliability are paramount.

Heat Sinks: It is used in conjunction with heat sinks to improve heat dissipation and thermal conductivity, preventing overheating and prolonging the lifespan of electronic components.

LED Lighting: It is applied to LED lighting fixtures and modules to enhance thermal transfer, reduce thermal resistance, and maintain optimal operating temperatures, improving efficiency and reliability.

Solar Panels: It is applied to solar panels and photovoltaic cells to create electrical connections, provide grounding, and protect components from environmental factors, ensuring efficient energy conversion and long-term reliability.

Wind Turbines: It is utilized in wind turbine generators and power electronics for EMI shielding, grounding, and thermal management, enhancing system performance and longevity.

Avionics and Aircraft Systems: It is used in avionics equipment, aircraft wiring, and electrical systems to provide EMI shielding, grounding, and electrical connections, ensuring reliable performance and safety.

Vehicle Electronics: It is employed in vehicle electronics, such as navigation systems, entertainment systems, and engine control units, to shield sensitive components from electromagnetic interference and ensure robust performance.

Antenna Design: It is incorporated into antenna designs for wireless communication systems to enhance signal transmission and reception, as well as to minimize interference from external sources.

Cable Shielding: It is applied to cables and connectors to shield them from external electromagnetic interference, improving signal integrity and reliability.

EMI Shielding: It is applied to electronic devices and circuitry to prevent electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring optimal performance and compliance with electromagnetic compatibility (EMC) standards.

Circuit Board Repair: It is used for repairing damaged traces, creating electrical connections, and reinforcing circuit boards, especially in high-frequency and high-power applications.

Grounding: It provides a reliable electrical connection for grounding components and circuits in electronic devices, reducing the risk of electrical noise and ensuring safety.

Electronics: Nano carbon copper foil tape is widely used in the electronics industry for applications such as:

Telecommunications: In the telecommunications industry, nano carbon copper foil tape is utilized for:

Aerospace and Automotive: Nano carbon copper foil tape finds applications in aerospace and automotive industries for:

Renewable Energy: In renewable energy applications, such as solar and wind power systems, nano carbon copper foil tape is used for:

Thermal Management: Nano carbon copper foil tape is employed in applications requiring efficient thermal management, such as:

Nano Carbon Copper Foil Tape Model List:

| Product Number: | Tape Thickness: | Liner Thickness: | Adhesion to Steel: |

|---|---|---|---|

| XH-50NCCFT | 50 microns | 100 microns | 7 N/25mm |

Nano Carbon Copper Foil Tape Actual Show Video:

Why Choose Us:

– Firstly, we are a professional manufacturer, with 16 years of adhesive tape production experience, has a huge advantage in price and quality.

– Secondly, we have a large number of customers and fast transportation channels to ensure the timeliness of customers receiving goods.

– Finally, we can provide quality assurance services for each customer, if there is a quality problem, free return.

– The Most important thing is that we always focus on becoming the world’s top adhesive tape manufacturer, the quality of our products is perfectly equal to that of 3M brands.