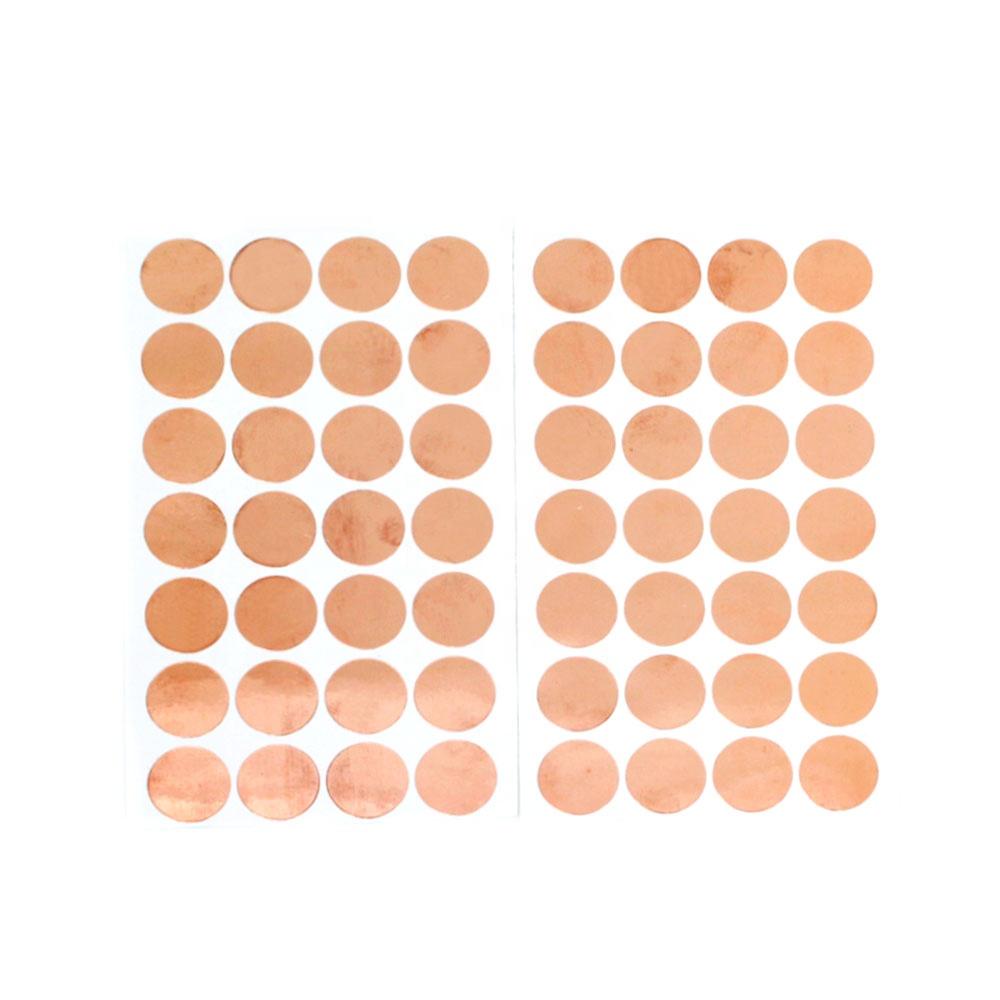

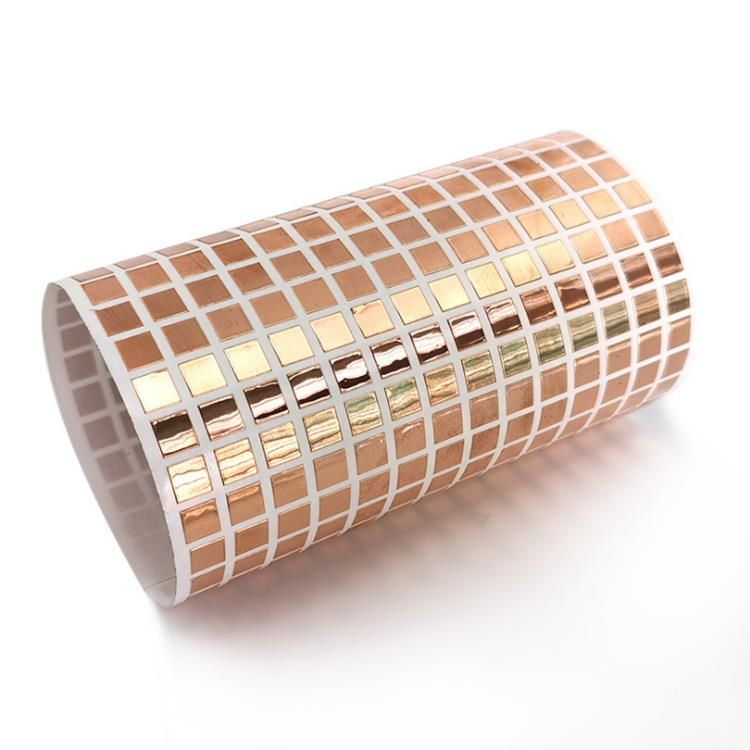

Die Cut Copper Foil Tape Description:

Die cut copper foil tape refers to copper foil tape that has been precision-cut into specific shapes or patterns using a die-cutting process. Here’s a detailed description:

Material: Die-cut copper foil tape is made from a thin sheet of copper foil, which is a highly conductive material known for its excellent electrical conductivity and corrosion resistance. The copper foil used in the tape is typically high purity and comes in various thicknesses to suit different applications.

Die-Cutting Process: Die-cutting is a manufacturing process used to cut materials into precise shapes or patterns using a custom-made cutting tool called a die. Die-cutting allows for the creation of intricate shapes with high accuracy and consistency. In the case of copper foil tape, the die-cutting process is used to cut the tape into specific shapes or dimensions according to the requirements of the application.

Adhesive Backing: Die-cut copper foil tape often features a pressure-sensitive adhesive backing that allows it to adhere to various surfaces, including metals, plastics, ceramics, and composites. The adhesive backing ensures secure bonding and easy installation without the need for additional adhesives or soldering.

Customization: Die-cut copper foil tape can be customized to meet specific application requirements. This includes custom shapes, sizes, and patterns tailored to fit the intended use. Customization options allow for precise integration into electronic circuits, components, or devices, optimizing performance and efficiency.

Electrical Conductivity: Copper foil tape offers high electrical conductivity, making it suitable for applications where electrical grounding, shielding, or conduction is required. Die-cut copper foil tape maintains this conductivity even after the die-cutting process, ensuring reliable electrical connections and performance.

Applications: Die-cut copper foil tape finds applications in various industries, including electronics, telecommunications, automotive, aerospace, renewable energy, and medical devices. It is used for EMI shielding, grounding, electrical connections, circuitry, and thermal management in electronic circuits, components, and devices.

Versatility: Die-cut copper foil tape is versatile and can be used in a wide range of applications where precision, reliability, and conductivity are critical. It provides an effective solution for creating custom electrical connections, shielding sensitive components from electromagnetic interference, and managing thermal dissipation in electronic systems.

Overall, die-cut copper foil tape offers a precise and customizable solution for electrical and electronic applications, providing high conductivity, reliable adhesion, and tailored performance to meet the specific needs of various industries and applications.

Die Cut Copper Foil Tape Application:

Die-cut copper foil tape finds numerous applications across various industries where precision, conductivity, and reliability are essential. Here are some common applications:

Overall, die-cut copper foil tape offers a precise and customizable solution for various electrical and electronic applications, providing high conductivity, EMI shielding, and reliable performance in industries ranging from electronics and telecommunications to automotive, renewable energy, and medical devices.

Electrodes: It is used in electrocardiogram (ECG) electrodes, defibrillator pads, and other medical electrodes for electrical conduction. Die-cut shapes of copper foil tape are integrated into electrode designs to ensure reliable electrical connections and patient safety.

Solar Panels: It is used in photovoltaic (PV) solar panels for electrical connections and grounding. Die-cut shapes of copper foil tape are applied to solar cells and modules to create interconnections and ensure efficient power generation.

Wind Turbines: It is employed in wind turbine generators for electrical grounding and EMI shielding. Die-cut copper foil tape is applied to wind turbine components to protect sensitive electronics from electromagnetic interference and environmental factors.

Electronic Components: It is used in vehicle electronics, such as sensors, control modules, and entertainment systems, for electrical connections and EMI shielding. Die-cut shapes of copper foil tape are applied to automotive electronics during manufacturing and assembly processes.

Battery Systems: It is utilized in electric and hybrid vehicles for battery management systems and electrical interconnections. Die-cut copper foil tape is applied to battery cells and modules to ensure reliable electrical connections and thermal management.

Connectorization: It is applied to connectors and cables to ensure secure electrical connections and minimize signal loss. Die-cut shapes of copper foil tape are used to create custom grounding straps, shielding wraps, and electrical pathways within telecommunications equipment and infrastructure.

Antenna Design: It is integrated into antenna designs to improve signal transmission and reception. Die-cut copper foil tape can be shaped and positioned to enhance the performance of antennas used in wireless communication systems.

Circuitry: It is employed in printed circuit boards (PCBs) for creating electrical connections between components, traces, and pads. Die-cut shapes of copper foil tape can be precisely placed and soldered onto PCBs, facilitating the assembly of complex electronic circuits.

EMI Shielding: It is utilized to provide electromagnetic interference (EMI) shielding for sensitive electronic components and circuits. Die-cut copper foil tape can be applied around critical components or along the edges of PCBs to prevent interference from external electromagnetic sources.

Electronics: Die-cut copper foil tape is extensively used in the electronics industry for:

Telecommunications: In the telecommunications sector, die-cut copper foil tape is used for:

Automotive: Die-cut copper foil tape is employed in the automotive industry for:

Renewable Energy: In the renewable energy sector, die-cut copper foil tape is utilized for:

Medical Devices: Die-cut copper foil tape is utilized in medical devices and equipment for:

Die Cut Copper Foil Tape Model List:

| Product Number: | Tape Thickness: | Tape Term: | Size: |

|---|---|---|---|

| XH-50CFT-S/D | 50 microns | Copper Foil Tape | Custom |

| XH-60CFT-S/D | 60 microns | Copper Foil Tape | Custom |

| XH-80CFT-S/D | 80 microns | Copper Foil Tape | Custom |

| XH-100CFT-S/D | 100 microns | Copper Foil Tape | Custom |

| XH-150CFT-S/D | 150 microns | Copper Foil Tape | Custom |

| XH-50CFT-D/D | 50 microns | Copper Foil Tape with Conductive Adhesive | Custom |

| XH-60CFT-D/D | 60 microns | Copper Foil Tape with Conductive Adhesive | Custom |

| XH-80CFT-D/D | 80 microns | Copper Foil Tape with Conductive Adhesive | Custom |

| XH-100CFT-D/D | 100 microns | Copper Foil Tape with Conductive Adhesive | Custom |

| XH-150CFT-D/D | 150 microns | Copper Foil Tape with Conductive Adhesive | Custom |

Die Cut Copper Foil Tape Actual Show Video:

Why Choose Us:

– Firstly, we are a professional manufacturer, with 16 years of adhesive tape production experience, has a huge advantage in price and quality.

– Secondly, we have a large number of customers and fast transportation channels to ensure the timeliness of customers receiving goods.

– Finally, we can provide quality assurance services for each customer, if there is a quality problem, free return.

– The Most important thing is that we always focus on becoming the world’s top adhesive tape manufacturer, the quality of our products is perfectly equal to that of 3M brands.